FILTER PRODUCTS

Categories

Information

Industrial Basket Strainers Australia

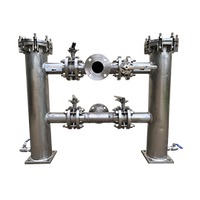

Defender Y, Simplex & Duplex Models

Dewater Products supplies heavy-duty basket strainers and Y strainers for industrial pipelines across Australia. Our Defender range includes Y Strainers, Simplex Basket Strainers, Duplex Basket Strainers, and custom-fabricated units built for flow-critical applications.

We deliver Australia-wide and offer technical guidance to help you select the right strainer for your flow rate, debris load, and pipeline design. Call 1300 271 290 or contact us online.

Fabricated Basket Strainer with davit arm and cable hoist

Fabricated Basket Strainer with davit arm and cable hoist

Compare Strainer Types

| Strainer Type | Orientation | Debris Capacity | Maintenance Access | Pressure Loss | Use Case |

|---|---|---|---|---|---|

| Y Strainer | Horizontal or Vertical | Low | Manual plug or blowdown | Moderate | Compact installs, high pressure |

| Simplex Basket Strainer | Horizontal Only | Medium–High | Top-opening basket | Low | General inline filtration |

| Duplex Basket Strainer | Horizontal Only | High | Dual baskets, isolatable | Low | Continuous flow, no downtime |

| Fabricated Basket Strainer | Horizontal Only | Custom | Davit/lift assist | Low | High-debris, large-bore pipelines |

Key Selection Considerations

- Flow rate: Basket strainers allow higher capacity flow with reduced pressure drop.

- Debris load: Choose basket strainers for longer run-times between cleaning.

- Installation space: Y strainers are more compact for tight installations.

- Cleaning frequency: Duplex strainers allow cleaning without stopping flow.

- Orientation: Basket strainers are horizontal-only; Y strainers offer more flexibility.

- Material compatibility: Options include stainless steel, cast steel, and ductile iron bodies with various mesh sizes.

Common Applications

- Process water filtration

- Pump and valve protection

- Cooling tower lines and HVAC

- Industrial wastewater and drainage

- Fire protection systems

- Chemical, oil, and food manufacturing

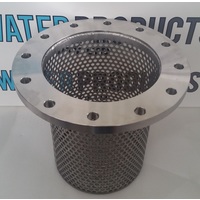

Sizes, Ratings & Materials

- Sizes: From 50mm to 600mm+ (custom sizes on request)

- Flange classes: Table D, Table E, ANSI 150LB, BS standard

- Body materials: Stainless Steel, Cast Iron, Cast Steel

- Designs: Inline, duplex, or fabricated with custom drain and lid options

Installation & Maintenance Notes

- Install with correct flow direction indicated by cast or labelled arrow

- Ensure sufficient clearance above basket strainers for basket removal

- Basket strainers must be installed horizontally

- Duplex strainers include isolation valves to divert flow between chambers

- Y strainers may require drain plug or blowdown valve for debris removal

Frequently Asked Questions

- Can I use a basket strainer for potable water?

Yes – stainless steel strainers with EPDM seals are suitable. Please confirm WRAS or relevant approvals before use. - What’s the benefit of a duplex basket strainer?

It allows uninterrupted flow during basket cleaning or maintenance – ideal for pumps and systems that cannot stop. - What pressure ratings are available?

Standard models handle up to 16 BAR. Fabricated and high-pressure versions are available on request. - Can strainers be custom-fabricated?

Yes – we supply custom strainers with davit arms, hoists, special mesh sizes, exotic materials and non-standard flanges. - Do you deliver across Australia?

Yes – we ship to all major cities and regional areas with fast lead times.

Need a Quotation or Technical Advice?

We support engineers, consultants, and contractors across water, mining, and process industries. Whether it’s a custom fabricated duplex basket strainer or a compact Y strainer, we’ll guide you to the right solution.

- Phone: 1300 271 290

- Email: Contact Us