FILTER PRODUCTS

Categories

Information

Expansion Joints

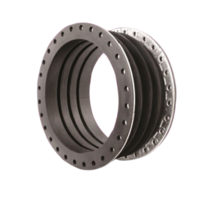

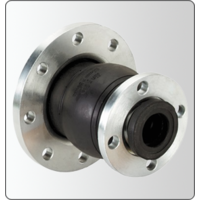

Rubber Expansion Joints (Rubber Bellows)

Designed to reduce pipeline stress, absorb vibration, and compensate for thermal movement, rubber expansion joints are a critical part of many industrial and infrastructure piping systems.

Dewater Products supplies a full range of flexible rubber bellows in multiple designs. Whether you're dealing with pump misalignment, water hammer, or pipework expansion, we have a solution engineered to perform under pressure.

All products include free delivery to metro areas across Australia.

For technical advice, contact us at sales@dewaterproducts.com.au or call 1300 271 290.

Why Engineers Choose Dewater:

- ✔️ 15+ years of pipeline component expertise

- ✔️ Trusted across mining, marine, wastewater & industrial sectors

- ✔️ Sizes from DN25 to DN3500 — with custom flanges & materials

- ✔️ Optional PTFE linings, vacuum rings, and control rods

- ✔️ Free metro shipping + fast, expert support nationwide

Control Rod Set - Rubber Expansion Joint Accessory

Control rods / Tie rods for Rubber Expansion Joints

Technical Specifications

- Size Range: DN25 to DN3500

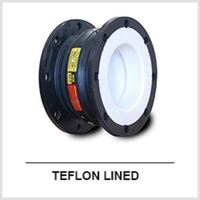

- Models: Single Sphere, Twin Sphere, Single/Double/Triple/Quad Arch (Filled or Unfilled), PTFE Lined, Reducers

- Materials: EPDM, Neoprene, NBR, Viton, Hypalon, Natural Rubber, PTFE

- Lining Options: Rubber or PTFE

- Flange Materials: Zinc Plated, Galvanised, 304/316 Stainless Steel, Epoxy-Coated Steel

- Pressure Ratings: Up to 25 BAR

- Vacuum Rating: Up to 750 mm Hg

- Applications: Industrial, HVAC, Marine, Chemicals, Slurry, Pumps, Mining, Dredging

- Free Delivery: Perth, Sydney, Melbourne, Brisbane, Adelaide, Canberra, Darwin, Hobart

Installation Guidelines

Before Installation:

- Ensure piping is well anchored and supported

- Use proper pipe guiding to avoid stress on the joint

- Inspect the joint for cracks or damage before installation

- Confirm pressure and temperature limits are not exceeded

- Clean and smooth flange faces are required

Step-by-Step Procedure:

- Apply lubricant to flange faces

- Align joint between flanges and insert bolts loosely

- Tighten bolts in a criss-cross sequence

- Do not over-tighten – follow torque specs

- Install control rods if needed

Additional Notes

- Flange standards: Table D, Table E, ANSI, DIN, BS, JIS

- Food-grade and WRAS-approved EPDM available for potable water

- Control rods recommended for unpredictable movement or high pressure

- Vacuum rings recommended when negative pressure exceeds 600mm H.g

- Custom designs and large diameter options available on request

Model Comparison Table

| Model | Fill Type | Size Range | Pressure Range | Common Materials |

|---|---|---|---|---|

| FSF - Single Sphere | Sphere | DN32 – DN600 | 7.5 – 16 BAR | EPDM / 316SS or Zinc |

| FSF-B - Single Sphere (Euro Spec) | Sphere | DN40 – DN300 | Up to 16 BAR | EPDM / Zinc |

| FTF - Twin Sphere | Sphere | DN32 – DN750 | Up to 16 BAR | EPDM / Zinc |

| Single Arch | Filled & Unfilled | DN50 – DN3500 | Up to 16 BAR | EPDM / Zinc |

| Double Arch | Filled & Unfilled | DN50 – DN1000 | Up to 16 BAR | EPDM / Zinc |

| Triple Arch | Filled & Unfilled | DN50 – DN3000 | Up to 16 BAR | EPDM / Zinc |

| Quad Arch | Filled & Unfilled | DN50 – DN1500 | Up to 16 BAR | EPDM / Zinc |

| Concentric / Eccentric Reducers | Filled & Unfilled | DN50 – DN600 | Up to 16 BAR | EPDM / Zinc |

| PTFE Lined FSF | Sphere | DN32 – DN600 | Up to 16 BAR | EPDM + PTFE / Zinc |